Keep the “sand out of the lubricant”

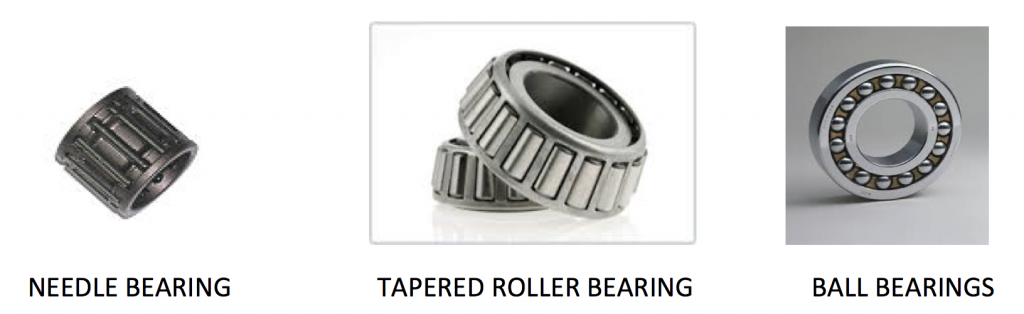

These words can be used for many things in life, but is most important when discussing roller bearing life span. The safety and reliability of your investment relies on constant upkeep and safety inspections. One area that is possibly overlooked is the inspection of your bearings and seals. Each mobile rubber tire gantry crane can have up to 1000 bearings (weather they are ball bearings, tapered roller bearings, roller bearings or needle bearings) that need to be inspected on a regular basis. Inspection should happen at regular intervals and when the hoist is being used, but a full certified inspection should happen once a year during a standard US Hoists Corporation Safety Service. To understand the best way to inspect and keep your bearings in optimum operation we need to review what types of bearing exist and what is the best way to care for them. There are possibly hundreds of different types of roller bearings and even more manufacturers. The below images capture the main units used on Travel Lifts and Planetary Winches.

Wikipedia lists the definition of a roller bearing as: “rolling-element bearing, also known as a rolling bearing,[1] is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two bearing rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.” The Rollers or Balls are made of hardened steel that ride against the casing in machined groves or planes, and are lubricated with a petroleum based lubricant. Keeping dirt and water out is very critical to the operation of roller bearings. Most modern bearings have to be replaced once the lubricant has stopped working due to water infiltration or dirt contamination.

Bearing failure is due to three main issues:

- Material Fatigue due to over use and age

- Destruction of lubricant.

- Infiltration of sand and dirt into the bearings inner workings.

In all the above scenarios, the inner balls/rollers can wear through the outer chase, causing the bearing to literally fall apart. Once this happens a serious safety problem can occur. The below picture is of two bearings that were not maintained properly and failure occurred. These bearings were used on a lifting winch, not only did this destroy the shaft seals when they came apart, the failure added stress and strain to the cast aluminum gear box casing, creating a crack that was unrepairable. This one was caught in the nick of time but could have caused great damage to the Travel Lift, Boat and or even personal injury. The gear oil that leaked into the marina created quite the environmental issue that no marina owner should ever have to go through.

“An ounce of prevention is worth more than pound of cure” Benjamin Franklin

“Keeping the sand out of the lubricant”

Visually inspect and clean off all locations that bearings are present. Most times bearings are hidden by a shaft seal or in a spot where visual inspection is not possible without taking major components apart. If you see a buildup of leaking oil and or a “damp” collection of dirt around an area that a bearing is located, it is best to clean the area with a “non-destructive” cleaner that will loosen dirt and oils. Wipe clean and check for leaks in the seal. DO NOT USE A POWER WASHER to clean these areas as it may destroy the seal and add unwanted water into your gear box. A leaky seal is the first indicator that a bearing is potentially starting to fail. If oil can escape from the inside of your Dodge Gear Box or Braden Winch, then water and dirt can get in. See the below diagram of the Fairfield Torque Hub used on many of our Acme Marine Hoists, item 1B (Shaft Seal) and item 5 (O-Rings) are critical for keeping the “Sand out of your lubricant”. Replacing an O-ring or shaft seal is a task any mechanic can complete but we believe it best to give US Hoists a call and discuss it beforehand, without the proper diagnosis of bearing or seal failure the problem can persist and potentially damage your investment. Pressed in bearings and factory sealed units are best serviced by our “factory certified technicians”. We carry all seals and bearings necessary to keep your Hoist running smooth and safely.

If you experience and “wobble” or “play” in your shaft address this issue right away by calling US Hoists Corp at 631-472-3030 to have our expert technicians fix the minor problem before it becomes a major failure

In a shameless plug for our team we recommend that our technicians do a safety inspection every year. During this safety inspection, we will review the travel lift for safety and OSHA compliance. If needed a list of recommendations will be reviewed with the marina manager and staff to create a repair plan based upon the safety factors, operational importance and other factors. “A safe lift is a profitable lift” give US Hoists a call at 631-472-3030 and set up your shaft seal replacement today.